Layers vs Broilers: Should you invest in Layers or Broilers? In the chicken industry in Kenya, there are three main sectors:

Layers, which are the chicken bred and raised to produce eggs, or broilers, chicken raised and bred to be slaughtered meat and the indigenous breeds.

Whatever sector you choose, you have to make the right decisions to make your chicken business a profitable one.

Let us take a look:

NB: Parts of this feature were first published in the Seeds of Gold agricultural journal that is published by the Nation Media Group.

Layers (Layers vs Broilers):

BY Dr. John Muchibi / Seeds of Gold (Veterinary Surgeon and the Animal Health Manager at Elgon Kenya).

The number of eggs from a flock and months in lay depend on among others the following variables: the breed of birds, management of the pullets (young hens) before lay, light management, nutrition and space available for your layers.

Breed

The decision of what breed to rear is taken by the farmer and then the hatchery supplies chicks from birds bred for optimum egg production with known potentials.

Flock management determines when and if your hens reach their egg-laying potential.

Management also determines whether the flock production curve fluctuates erratically or follows the established pattern.

Pullet management

It is important to manage pullets correctly particularly in the areas of nutrition, light management and disease control.

At the point of lay, a pullet may weigh about 1.5kg. Birds that start laying before attaining the correct size may be prone to prolapses of the cloaca.

Banks to pay Sh. 2 million fine for every CRB-listed Kenyan they deny loan

Deworm monthly after 8 weeks. De-beak between 8 and 12 weeks.

De-beaking should be done by qualified personnel. The lower beak should be longer to enable the hen ‘scoop’ feeds.

Success or failure of the layer enterprise will depend, to a large extent, on the management of the pullets.

Light management

Unknown to many poultry farmers, light is much more important for the hens than just for sight. Light plays a significant role in poultry reproduction, growth and behaviour.

Light controls sexual maturity in birds. Layers should be given 24 hours of light for the first four weeks. Increasing day-length (light) leads to faster sexual maturity hence earlier lay.

Pullets stimulated to lay before week 17 or 18 may never achieve their lifetime productivity potential. For maximum egg production, 16 hours of light is required at peak lay.

At no time should photoperiod be reduced during lay. A word of caution though: too much light in a layers’ house may lead to vices such as cannibalism, aggression and even egg eating.

This informs the cardinal rule of building a chicken house in an east-west orientation.

The optimal lighting is that which would allow the farmer to read a copy of the ‘Seeds of Gold’ from the darkest corner.

Nutrition

Laying hens require balanced feed to sustain maximum egg production over time.

They require energy, proteins, fats, minerals and vitamins. Given that feeds account for over 70 per cent of rearing costs, many farmers attempt shortcuts.

Crooked KRA employees taking home Sh. 500,000 in bribes daily

Some give their hens ‘breakfast,’ ‘lunch’ and ‘supper,’ in which case the birds do not get enough feeds, while others add other feed ingredients to commercial feeds.

Again unknown to many, this ‘adulteration’ serves to distort the formulation and eventually, the performance of birds.

Cumulatively, each layer chick consumes about 2kg of chick and duck mash between day old to eight weeks.

One growing pullet consumes about 7kg growers mash cumulatively between 9 and 20 weeks. A layer bird cumulatively consumes about 50kg of mash for her entire optimal laying life of 12 months (about 140g/day).

If a farmer finds that their hens are eating more, it is most likely that they have a lot of spillage (they eat more when it is cold).

Spillage maybe corrected by raising or lowering the feeders so the feed level is the same as the back of the hens.

Water is a critical but often overlooked nutrient. Birds and indeed all animals can survive longer without feed/food than without water.

At normal temperatures, layers consume twice as much water as they consume feeds. During periods of high temperatures, water consumption may double or even quadruple.

The shocking salary and allowances Joshua Oigara earns as KCB CEO

For good lay percentages, ensure birds are supplied with adequate quantities and quality water.

Floor space for layers

For optimal performance, each layer requires 2 square feet of space. Incorporate perches on which birds prefer to sleep at night.

The use of perches also helps concentrate manure in single locations making cleaning easier. Moreover, chicken have a desire to perch, so providing for this natural behaviour contributes to animal welfare.

Provide laying nests covered with black polythene; a nest measuring 1ft x 1ft is sufficient for five hens.

The floor should be covered with 4 inches wood shavings to absorb moisture and cushion the birds from the cold floor.

Identification of laying hens

These tend to be smaller, have bright red combs/wattle; additionally, three middle fingers fit between the pubic bones in a laying bird.

Expected performance

Mortality at rearing should not exceed 5 per cent.

Mortality at lay should not be more than 8 per cent.

Age at start of lay is 18 to 20 weeks

Total egg production per hen for her lifetime, about 318 eggs.

Average weekly egg production:

• Week 19 – 6%

• Week 20 – 20%

• Week 21 – 50%

• Week 22 – 78%

• Week 23-43 – 90 – 93%

• Week 44-60 – 80-89%

• Week 61-73 – 70-79%

• Week 73 – 80 – 70 – 65%

Reasons hens stop laying

Normally, a hen would lay between 24 and 27 eggs in a month.

This is because it takes 26 hours for an egg to be formed. Reasons why hens would stop or reduce laying include:

1. Laying for more than 12 months.

2. Change in weather conditions leading to stress.

3. Vaccination, de-beaking and transportation stresses.

4. Disturbances like when removing litter, predators and noises.

5. Rationing feeds.

6. Feeding poor quality feeds.

7. Insufficient fresh, clean drinking water.

8. Exposure to short photoperiod hours of light.

9. Infestation with Internal and/or external parasites.

10. Disease situation.

11. When the birds are laying and eating eggs/deficiencies.

12. When other predators are eating eggs e.g cats, rats, snakes.

The good news is that a farmer can do something to address most of the causes of reduced laying.

Broilers (Layers vs Broilers):

BY Dr. Joseph Mugachia / Seeds of Gold.

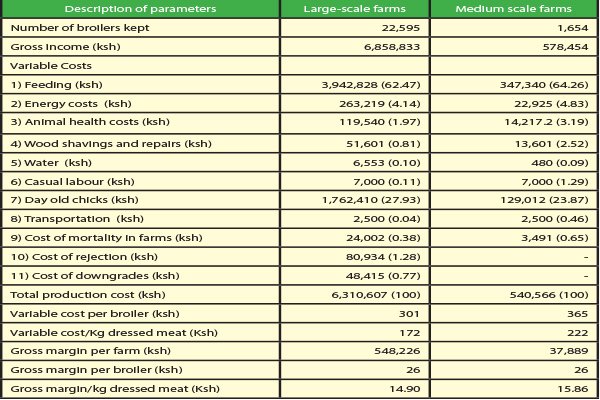

A study that was carried out by four researchers from the University of Nairobi, Kenchic Ltd and the World Animal Protection worked with large farms comprising 22,595 broilers and medium ones with 1,654 broilers.

From the findings, large scale broiler farmers spent almost half what the medium scale ones spent on flock health.

Reuben Kimani: I turned down Sh. 25,000 plots, now they’re worth millions

They also spent three times less in wood shaving and 112 times less in labour and transport.

The mortality cost on the farm was two times lower. This benefit is attributed to the economies of scale. For instance, most poultry vaccines and medicines are packed in bulk, usually for 100-500 birds. When a farmer has less than 100, she still has to buy the pack, resulting in wastage.

The cost of rejection and downgrading of birds and carcasses was high for large scale farmers at Sh129,349 while there was none with small scale producers.

This may have resulted from inadequate care during rearing and transport due to large numbers.

It cost Sh301 to rear a broiler on the large-scale farm and 365 for the medium scale. It also cost Sh172 to produce a kilo of meat on large scale farms and Sh222 for medium scale farms.

Interestingly, the gross profit for producing a kilo of dressed meat on large scale farms was about Sh15 and Sh16 for medium scale farms.

It means there is no much difference in profit if one produces the chickens only once. This is called one production cycle.

However, the large number of birds in large scale production gives a good multiplier effect.

A farmer should ensure he produces the birds at least four times a year. These are called cycles. A well-managed large-scale farm can have five to seven cycles a year, raising profit to about 47 per cent.

Feeding comprises 63 per cent of the total cost in large-scale farming and 65 in medium scale.

I worked in Iraq between 1998 and 2003 where broiler production was one of our major economic and food security activities.

PROFITABLE BROILER PRODUCTION

We determined that profitable broiler production requires a farmer to keep at least 3,300 birds and four cycles every year.

The legal and suspicious ways Moi family’s multi-billion empire was built

There were hatcheries supplying day-old chicks, grower farms, slaughterhouses and meat distributors. Meat was finally supplied to consumers through retail outlets like shops, supermarkets and hotels.

The government regulated poultry production, ensuring every level had a sufficient number of productive players to serve the next point of the value chain.

Our programme ensured that the inputs needed were readily available and the produce efficiently moved to the market.

Kenya lacks a regulation mechanism that would prevent under and overproduction of broilers. There are few hatcheries and a high demand for day-old chicks.

This results in farmers being supplied with a fraction of their needs. Consequently, a majority of farmers are ultra-small scale producers.

This keeps hatcheries in business because they sell all chicks but farmers are in a vicious cycle of scarcity and farm closure.

Am into turkey farming and its quite promising.

Have also kuroiler chicken breeds.

I havent seen the cost of buying day old chicks…..would that mean you run into negative profit/losses?