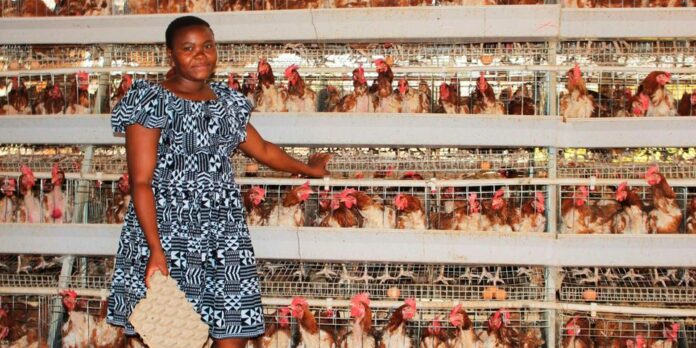

Anna Ndunda’s poultry farming empire has an elaborate battery cage system. This system gives one an insight into how he runs her chicken farm, and how seriously she takes her chicken business. She says that this system helps her collect clean eggs.

“The cage system enables us to monitor the health and productivity of individual birds. This prompts appropriate action such as the isolation of a sick bird. More importantly, the battery cage system enhances efficiency in feed and water use by reducing wastage,” she said in a past media interview.

In a past interview with local media, Ndunda explained that she starts with sourcing chicks from certified dealers. She buys day-old chicks from a supplier in Nairobi and puts them in a brooder powered by specially designed pots which run on charcoal. The chicks are also put on a vaccination regimen against common diseases.

Wycliffe Mwangale: Kienyeji chicken farmer reaping big from 4,500 poultry empire

“We stock Issa Brown, a hybrid chicken famed for its egg laying. We transfer the chicks from the brooder to the cages when they are three months old. They start hatching when they are 18-20 weeks old and don’t stop until they are 18 months old,” she told Seeds of Gold in a past interview.

Ndunda says that when she started out, she kept chicken for meat and eggs under the deep litter system in a small scale venture which struggled to carry its weight as it was less profitable.

This changed when she visited President William Ruto’s chicken farm at Sugoi in Uasin Gishu County for benchmarking. “Here, I learned about the cage system and the importance of clean water and high-quality feeds in chicken production. I also learned about the gradual introduction of growers’ mash to chicks,” she said.

With 1, 500 layers, Ndunda is among the biggest chicken farmers in the county. She collects 43 trays of eggs daily. Wholesalers buy the eggs from her farm, which they sell in Wote Township to individuals, restaurants and hotels. Her customers cite the size and cleanliness of the eggs, attributes Anna associates with the battery cage system. In spite of her output, Anna’s 43 trays of eggs a day are nowhere near enough to meet the demand for eggs in this area, meaning it is a viable business to invest in.

In a semi-arid region known for drought and crop failure, Anna cites water and feed as her biggest challenges. She spends Sh. 11, 000 daily on commercial feeds and Sh. 10, 000 to buy water every month. Ndunda now plans to expand her stock to 10,000 birds. She also plans to carve out an extra revenue stream from the birds by setting up a model farm and opening it for training on poultry farming and egg production.

According to Nicholas Muyale, the chairman of the Kenya Veterinary Association, feeds take up 70 per cent of the cost of producing eggs in Kenya. This makes Kenyan eggs uncompetitive in the market compared to eggs imported from Uganda. “The cost of producing an egg is hinged on feed. 70 per cent of the inputs on egg production is on feed. Uganda produces the raw materials for making feeds and does farm feed formulations. In Kenya, we do commercial feed formulation, and because we import most of the raw materials, the production cost is high,” he told local media.

He advises poultry farmers to embrace new technologies of feed production such as the use of Black Soldier Fly maggots to cut on the cost of producing feed and make the egg production ventures profitable.