Biogas can be produced by anaerobic digestion or fermentation of biodegradable materials such as biomass, manure, sewage, municipal waste, green waste and energy crops.

The biogas produced from a digester is comprised primarily of methane, carbon dioxide and other trace gases. When you build a biogas plant, methane, hydrogen, carbon monoxide and other trace gases are produced… but methane is the main combustible gas.

The main components of a simple biogas system will include:

1) Inlet pipe

2) digester tank

3) gas holder tank

4) slurry outlet pipe

5) gas outlet pipe

A digester tank may be the costly item here depending on its capacity.

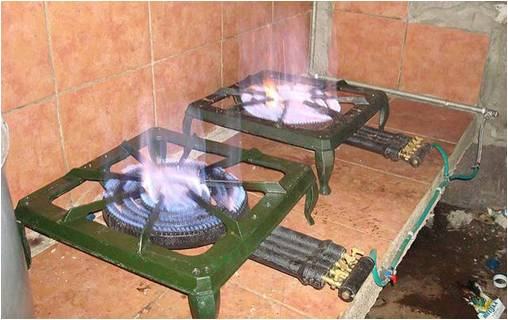

For the equipment to produce gas, the digester is filled halfway with bio-degradable materials, like cow dung mixed with water in equal ratio. It is then refilled with smaller amount every two weeks. The equipment starts producing gas after seven days. The gas will be produced constantly as long as it is fed daily.

The equipment comes in three pieces: A round shaped anaerobic digester tank with an inlet, a displacement tank with an outlet, and the cooker connected using a gas outlet pipe.

You may also opt to use the Blueflame BiosluriGaz technology which doesn’t require you to dig up pits to install your biogas system. Unlike the previous biogas, which was dug underground, the latest technology is a plastic tank that is fitted with necessary systems to produce the biogas and fertiliser.

To set up this technology, a farmer requires a flat ground. You will need to cover your biogas system with a stable polythene bag to keep in the moisture. You will then fill up your system with cow dung. Depending on size, you may require 1,500kg of cow dung and 1,500 litres of water for the larger unit and 900kg of cow dung and 900 litres of water for a smaller unit.

The mixing ration of water to dung should be 1:1, which is for every bucket of cow dung; a similar amount of water should be used. Once full, the system’s gas holder is emptied to release the air trapped inside. The gas will be accumulated in the gas holder. Once the gas is extracted from the dung, what remains is nutrient-organic fertiliser.